Summary

In my previous article Chatbots, AI and Docker! I talked about a little of the theory behind this but for this article I wanted to fully go down the rabbit hole and produced my own chatbot. To do this, I had to find an updated chatterbot fork, learn a little more python to handle dependencies better, create my own fork of corpus/training material and learn Google Cloud Run. Ultimately you can skip straight to the source if you like. That’s the great part of GitOps/IaC

And Then Some

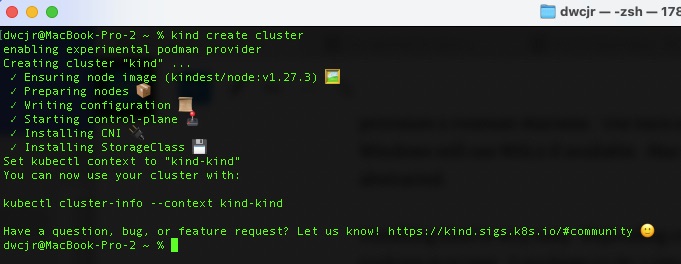

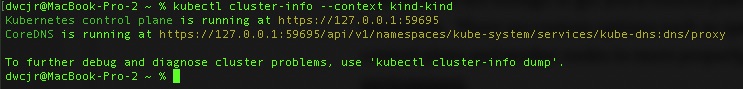

Previously, I had a workable local instance that I was able to host in podman/kind but I wanted to put this in my hosting environment on Google. In order to personalize this, I wanted to be able to add some training data and use some better practices. Having previously used Google App Engine, assumedly that would naturally be the landing place for this. I then ran into some hiccups and came across Cloud Run which was not originally available and seemed like a suitable fit as it is built for containerized workflows. It provided me a way to use my existing Dockerfile to unify the build and deploy. For tools, I have a separate build and test workflow in my cloudbuild.yaml.

Get on with Chatbots!

In my last article, I mentioned I had to find a fork of chatterbot because it has not been recently maintained. In reality though it only allowed command line prompting which is not terribly useful for a wider audience to test. I came across this amazing medium post which I have to give full credit for (and do in the html as well). The skin is pretty amazing. It also provides a wealth of in depth details.

For the web framework, I opted to use Flask and gunicorn which was fairly trivial to get going after finding that great medium post above.

Training Data

Without any training data AI/ML does not really exist. It needs to be pre-trained and/or train “on the job”. For this, chatterbot-corpus comes into play. This is a pre-built training data set for the chatterbot library. It has some decent basic training. I wanted to be able to add my own and based on the input of casmith, its in python so shouldn’t it be able to converse with Monty Python quotes? So I did and created my own section for that.

categories:

- Monty

- humor

conversations:

- - What is your name?

- My name is Sir Lancelot of Camelot.

- - What is your quest?

- To seek the Holy Grail.

- - What is the air speed velocity of an unladen swallow?

- What do you mean? An African or European swallow?

- - How do know so much about swallows?

- Well, you have to know these things when you're a king, you know.I have the real-time training disabled or rather put my chatterbot into read only mode because the internet can be a cruel place and I don’t need my creation coming home with a foul mouth! For my lab, the training is loaded at image creation time. This is primarily because its using the default sqlite back end. I could easily use a database for this and load the training out of band so it doesn’t require a deploy.

Logic Adapters

You may be thinking this is a simple bot that’s just doing string matching to figure out how to respond. For the most part you’re correct. This is not deep learning and it doesn’t fully understand what you are asking. With that said its very extensible with multiple logic adapters. The default is a “BestMatch” based on text input. Others allow it to report time and do math. It will weigh the confidence of the response on each adapter to let the highest scoring/weighing response win. Pretty neat!

chatbot = ChatBot(

"Sure, Not",

logic_adapters=[

'chatterbot.logic.BestMatch',

'chatterbot.logic.MathematicalEvaluation',

'chatterbot.logic.TimeLogicAdapter'

],

read_only=True

)Over To The Infrastructure

For all of this, it starts with a Dockerfile. I already had this but it was a little bloated with build dependencies. Therefore, I created a multistage image using virtual python environment as guided by https://pythonspeed.com/articles/multi-stage-docker-python. I am not new to multistage images. My golang images use it. I was, however, new to doing this with Python. Not only did it reduce my image size down 100MB but it also removed 30 vulnerabilities from the images because of a dependency on git for some of the python libraries.

Cloud Run

To get deployed to Cloud Run, it was pretty simple although there were a few trial an errors due to permissions. The service account needed Cloud Run Admin access. Aside from that, this pumped everything through and let me keep my singular Dockerfile.

steps:

# Docker Build

- name: 'gcr.io/cloud-builders/docker'

args: ['build', '-t',

'us.gcr.io/${PROJECT_ID}/chatbot:${SHORT_SHA}', '.']

# Docker push to Google Artifact Registry

- name: 'gcr.io/cloud-builders/docker'

args: ['push', 'us.gcr.io/${PROJECT_ID}/chatbot:${SHORT_SHA}']

# Deploy to Cloud Run

- name: google/cloud-sdk

args: ['gcloud', 'run', 'deploy', 'chatbot',

'--image=us.gcr.io/${PROJECT_ID}/chatbot:${SHORT_SHA}',

'--region', 'us-central1', '--platform', 'managed',

'--allow-unauthenticated', '--port', '5000', '--memory', '256Mi',

'--no-cpu-boost']

# Store images in Google Artifact Registry

images:

- us.gcr.io/${PROJECT_ID}/chatbot:${SHORT_SHA}

It really was this simple since I had a working local environment and working Dockerfile. Just don’t look at my commit history 🙂 Quite a few silly mistakes were made if you look deep enough.

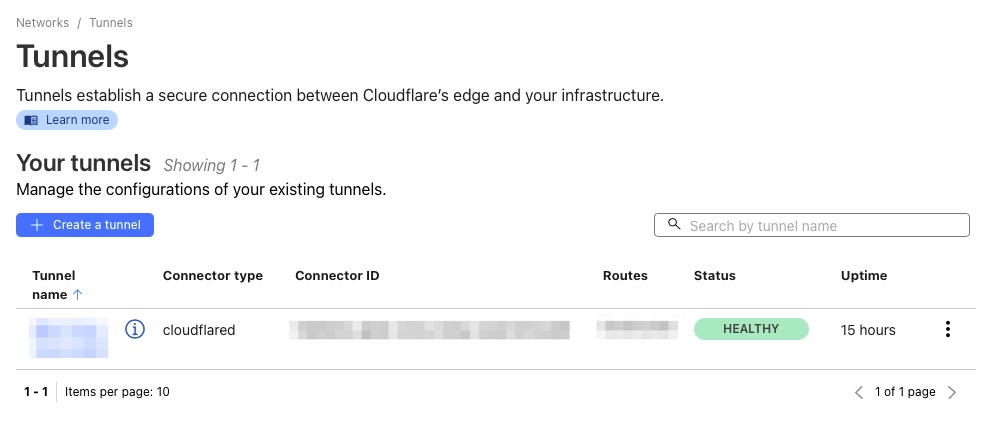

Caveat

Google App Engine lets you use custom domain mapping and bring your own certificates. I use Cloudflare to protect my entire environment and for this in GAE I placed a Cloudflare Origin certificate to help prevent it from being accessed by the outside world as no browser would trust it bypassing Cloudflare.

Google Cloud run has a preview feature of custom domain mapping. The easiest of the options doesn’t support custom certificates and therefore wants to issue you a certificate. The temp workaround for this is to not proxy through Cloudflare until the certificate is issued and then turn on proxy. Rinse and repeat yearly when the cert needs to be renewed.

I have to imagine this will get rectified once out of preview to be feature parity with Google App Engine since it seems Cloud Run intends to replace GAE.

Credits

For Multi-stage help with Python Docker Images – https://pythonspeed.com/articles/multi-stage-docker-python

For the entire UI of this demo/test – https://medium.com/@kumaramanjha2901/building-a-chatbot-in-python-using-chatterbot-and-deploying-it-on-web-7a66871e1d9b